Mechanization is a general trend in the industrial industry. The use of mechanized production can greatly reduce the expenditure of human cost. At the same time, mechanized equipment can greatly improve the efficiency of production and reduce the expenditure of human cost. Especially in the textile industry, in the past, the textile industry needed a lot of manpower. Now with the development of mechanization, the textile industry has also benefited a lot. For example, the use of non-woven machinery and equipment can play a great role. Let's have a look.

The main content of how to protect the production line of non-woven machinery and equipment is cleaning, fastening, adjustment, smoothness and anti-corrosion. It is necessary for the Mechanical Department of each project to strictly implement various protection operations according to the protection manual and protection procedures of mechanical equipment, reduce the wear speed of parts, eliminate the risk of defects and extend the service life of machinery. The following operations shall be done:

1. Routine protection

Based on cleaning, smoothness, inspection and fastening, routine inspection and protection shall be carried out before, during and after each shift. Routine protection is completed independently by the manipulator.

2. Timing protection

According to the protection requirements of various mechanical equipment, it is necessary to carry out corresponding timing protection after reaching the regular operation hours or regular time.

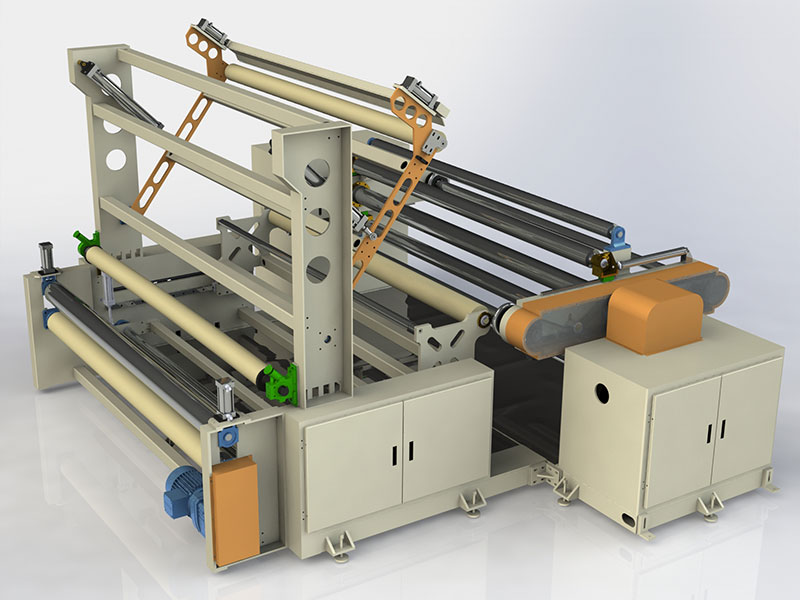

Non woven fabric equipment is a machine for processing non-woven fabrics and producing various products. Non woven fabric equipment mainly includes: non-woven fabric bag machine, non-woven fabric slitting machine, non-woven surgical garment machine, non-woven fabric filter cotton weaving machine, non-woven fabric shoe cover machine, non-woven fabric glove machine, non-woven fabric fruit cover machine, non-woven fabric doctor hat machine, non-woven fabric nurse hat machine, non-woven fabric pillow core cover machine, non-woven fabric eye mask machine Non woven fabric punching machine, non-woven fabric rewinder and other machines.

For example: performance and characteristics of non-woven bag making machine: the machine is applicable to PP non-woven cloth as raw material, and can process all kinds of non-woven cloth bags with different specifications and shapes, such as flat bags, handbags, vest bags, flour bags, film covered bags, etc. the machine integrates electromechanical and uses LCD touch screen operation. Equipped with walking fixed length, photoelectric tracking, computer active, computer active edge correction, accurate and stable.

No matter what equipment it is, after frequent use, we should pay attention to the relevant work of maintenance and repair. The more non-woven machinery is no exception, such equipment is frequently used when in use. Because the demand of the textile industry is great, we must do a good job in the relevant maintenance of non-woven machinery after the equipment stops running. Through the reading of the above contents, do you know what the maintenance work of non-woven machinery is?

![[field:companyname]](/template/sllwen/skin/images/code.jpg)