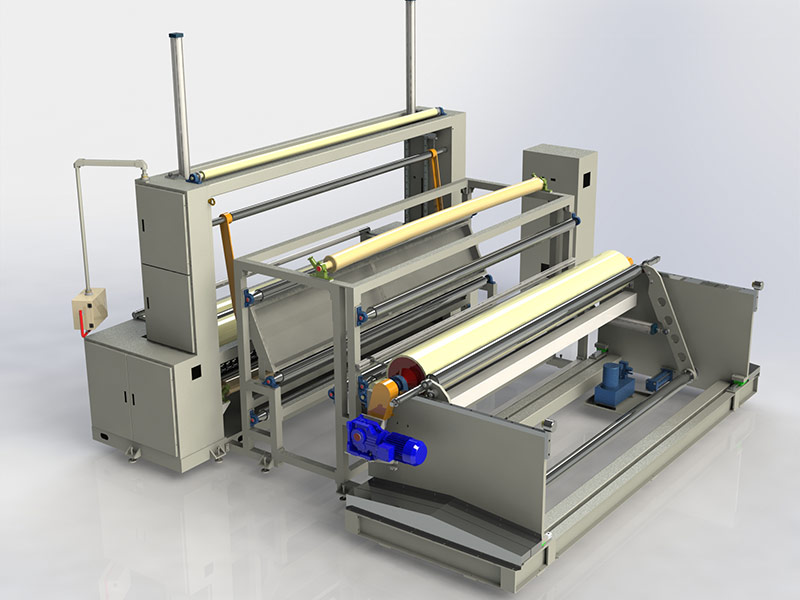

Clothing, food, housing and transportation are the necessary needs of our life. With the development of technology, in order to meet people's living needs, many needs have become very large. Take the cloth we need. The rapid development of the textile industry has brought us a wide variety of cloth. At the same time, in order to improve the production output, more mechanical equipment are used in the textile industry, For example, non-woven fabric slitting machine is one of the more used equipment. Let's take a look at the relevant introduction of non-woven fabric slitting machine.

The linear pressure of the paper pressing roller, which pressurizes the paper roll during rewinding. In the initial stage of rewinding, the paper pressing roller provides additional load for the paper roll and acts together with the front and rear bottom rollers to provide a rewinding force for the paper roll. With the increase of roll diameter, the position of the paper pressing roller gradually rises, and the load provided by the paper pressing roller gradually decreases. When the roll diameter reaches a certain value, the load provided by the paper pressing roller is zero. At this time, it exists only as a device to maintain the position of the paper roll. The pressure control program of the paper pressing roller must be selected according to the paper quality and final diameter. In general, the pressure of the paper pressing roller is automatically controlled according to the preset pressure curve, and the operator does not need to change it.

Tension control of unwinding: during rewinding a set of paper rolls, the rewinding tension shall be avoided as much as possible to ensure that the winding tension of the slitting rewinder is uniform inside and outside. Secondly, in the rewinding process, if the tension control of the paper web is too small, the paper roll will collapse or slip on the bottom roll, resulting in paper diseases such as wrinkles and paper interleaving. If the tension control is too large, it will cause roll explosion or damage the paper core. Therefore, it is very necessary to keep the actual control value of tension constant during the rewinding operation of the web and install a well adjusted inertia instantaneous compensation regulator in the tension closed-loop control system.

The service environment of slitter equipment directly affects the characteristics and service life of electrical appliances and parts. The environment for installing equipment shall:

1. Keep the room well ventilated.

2. Ambient temperature - 10 ℃ + 40 ℃.

3. Try to avoid high temperature and humidity. The humidity is less than 90% RH and there is no rain.

4. Avoid direct sunlight.

5. No flammable and corrosive gases and liquids.

6. The installation foundation is fixed without vibration.

7. No electromagnetic interference and keep away from interference sources.

No matter what industry, the use of mechanical equipment is to increase the efficiency of production, and the textile industry is no exception. In addition, people's demand for cloth has become greater. It is inevitable for the textile industry to use mechanical equipment when producing cloth, and the non-woven fabric slitter is only one of many equipment. Through the introduction of the non-woven fabric slitting machine, do you have a certain understanding of the non-woven fabric slitting machine? If you want to know more, welcome to consult.

![[field:companyname]](/template/sllwen/skin/images/code.jpg)