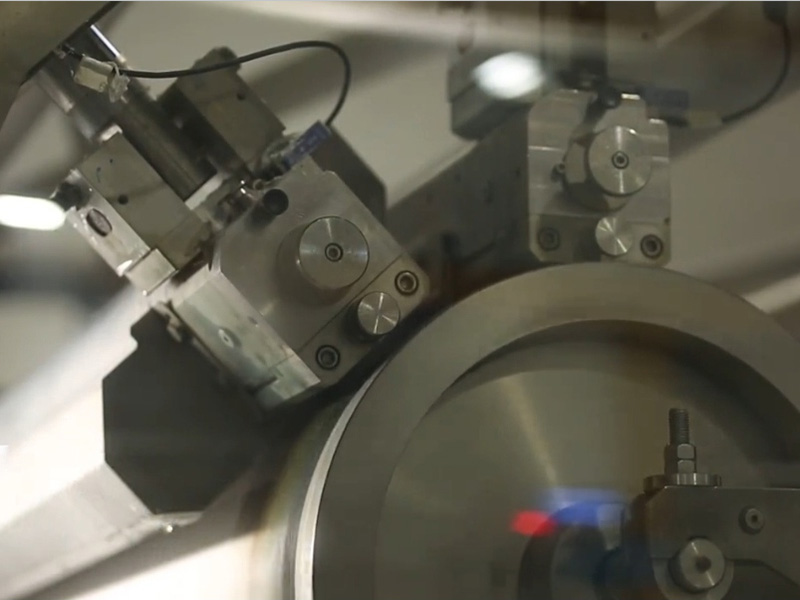

The textile industry is certainly no stranger. There are many different materials of light fabrics for the clothes we wear now. Fabrics of different materials have different characteristics and can be used in different places. These fabrics can even play an important role in. Now these fabrics are widely used, which makes the textile industry have to use mechanical production equipment. For example, the spunlaced production line we want to talk about below is one of the production of spunlaced fabrics. Let's take a look at the introduction of spunlaced production line.

1、 The main differences of spunlaced production line are: different gram weight, different hand feel, different material and surface,

1. Different gram weight

(1) The gram weight of spunlaced nonwovens is not as high as that of needle punched nonwovens. The weight of spunlaced nonwovens is usually less than 80g, especially 120-250g, but few.

(2) The gram weight of needled nonwovens is higher than that of spunlaced nonwovens, which is generally thicker and weighs more than 80 grams.

2. It feels different

(1) Spunlaced production line; Spunlaced non-woven fabric makes it feel more delicate.

(2) Needle punched nonwovens have coarse fiber and rough hand feel.

3. Different material surfaces

(1) The surface of spunlaced nonwovens is longitudinally provided with thin Spunlaced wires.

(2) There are small pinholes on the surface of needle punched nonwovens. This product has unique adsorption capacity and liquid absorption capacity, excellent dust-free, flexibility, antistatic, no damage to object surface, toughness and durability. Do not use any chemical adhesives.

2、 Operation characteristics of spunlaced production line:

1. No dust, no fiber falling off and no fiber debris during use, so as to ensure the wiping quality;

2. Uniform weaving, with good vertical and horizontal tension

3. The material is soft without any scratch and damage to the object surface;

4. Strong water absorption capacity, more than four times faster than ordinary cotton cloth;

5. Remove water and oil stains;

6. Excellent solubility resistance;

7. No static electricity;

3、 Application fields of spunlaced production line:

1. Industrial wipes: mainly used in electronic industry, spraying technology, scientific research institutes and laboratories; Printing industry, mechanical processing, food and drug production equipment cleaning, automobile beauty, instrument surface cleaning, etc.

Spunlaced production line is a kind of equipment widely used in the textile industry, mainly because Spunlaced cloth is widely used, so Spunlaced production line will be used more and more. Such a kind of equipment that can reduce labor cost and improve production efficiency is naturally widely used and favored. The advantages of spunlaced production line may not be clear to unfamiliar people. Through reading the above contents, do you have a certain understanding of spunlaced production line?

![[field:companyname]](/template/sllwen/skin/images/code.jpg)